Why Sample Approval Takes Longer Than You Budgeted for Bamboo Cutlery Orders

The hidden time sink in sustainable cutlery procurement that consistently catches buyers off guard.

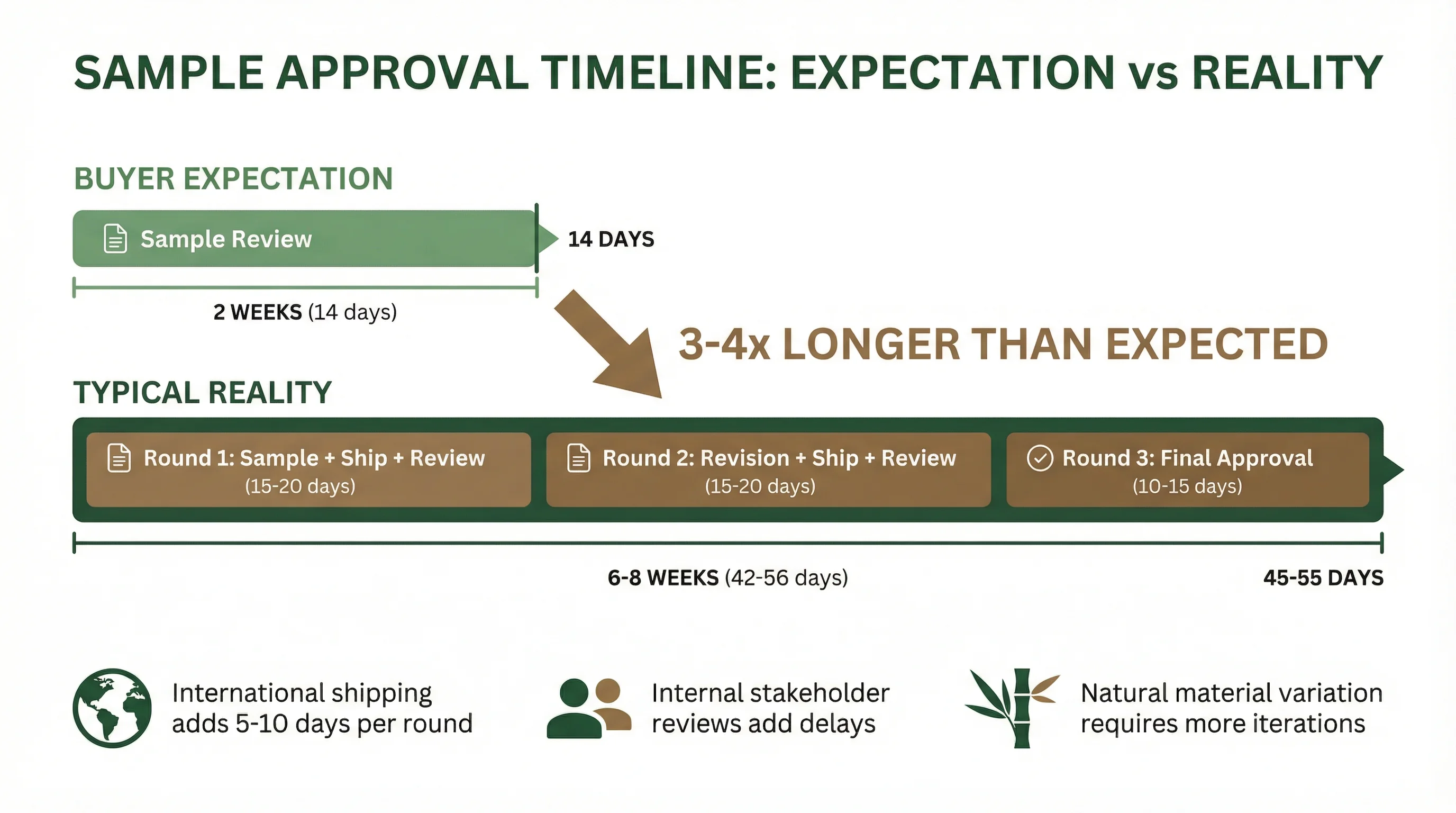

When procurement teams map out their timeline for a bamboo cutlery order, the sample approval phase typically receives a single line item: "Sample Review – 2 weeks." In practice, this is often where lead time calculations start to unravel. The gap between what buyers budget for sample approval and what actually occurs on the factory floor reveals a fundamental misunderstanding of how natural material products move through the pre-production process.

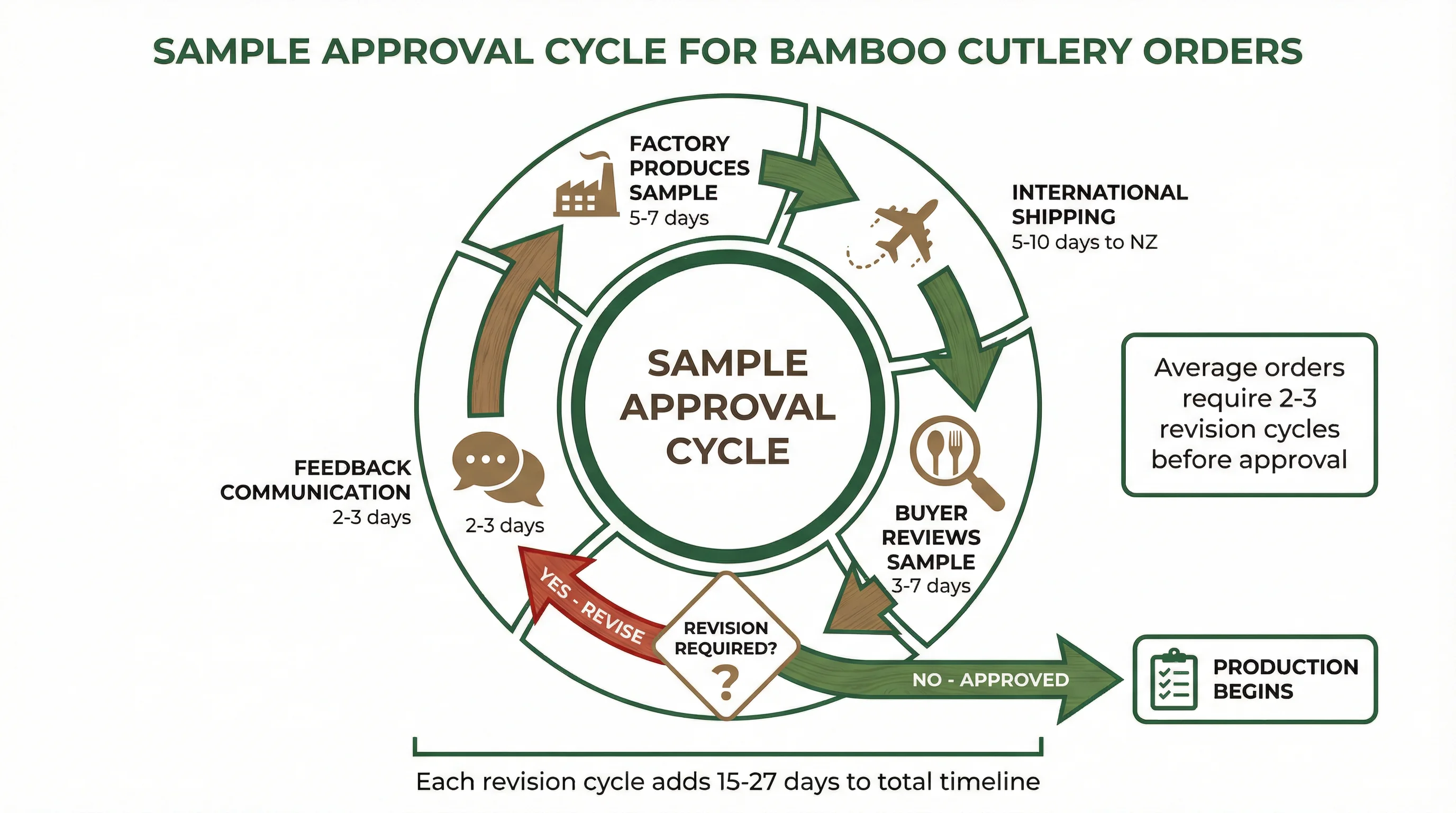

From a production management perspective, the sample phase isn't a single event—it's an iterative cycle that depends on variables buyers rarely see. When a procurement manager requests a sample of laser-engraved bamboo forks, they're imagining a straightforward process: factory makes sample, ships it, buyer approves, production begins. The reality involves material selection, engraving depth calibration, finish testing, packaging mock-ups, and often multiple rounds of adjustment before the sample matches the buyer's mental image of their product.

The first sample rarely matches expectations perfectly. This isn't a quality issue—it's a communication reality. Written specifications translate differently across languages and manufacturing contexts. When a buyer requests "natural bamboo colour," the factory interprets this against their standard material grades. When the sample arrives and the buyer expected a lighter tone, we've just added another cycle to the timeline. Each revision cycle adds seven to fourteen days at minimum: time for the factory to understand the feedback, source or adjust materials, produce the revised sample, and ship it internationally.

For New Zealand buyers specifically, the geographic factor compounds this challenge. Shipping samples via air express from Chinese manufacturing regions to Auckland or Wellington takes five to ten business days, depending on customs processing and courier service. A sample that leaves Ningbo on Monday might not reach the buyer's desk until the following week—or longer if it crosses a public holiday period in either country. This transit time applies to every sample iteration, meaning a three-round approval process includes three separate international shipping cycles.

Internal approval processes within the buying organisation add another layer of delay that factories cannot control or predict. When a sample arrives at a corporate office, it often needs to pass through multiple stakeholders: the procurement manager who ordered it, the marketing team who will use the branded cutlery at events, the sustainability officer who needs to verify material claims, and sometimes legal or compliance reviewers. Each stakeholder may have different criteria and availability. A sample that sits on someone's desk for a week waiting for review is a week added to the total timeline—time that never appears in the factory's production schedule but absolutely affects the final delivery date.

Natural materials introduce variability that synthetic products don't face. A bamboo sample approved today may look slightly different from the production batch three months later, because bamboo harvested in different seasons or from different plantation regions exhibits natural colour and grain variations. Experienced buyers understand this and approve samples with acceptable tolerance ranges. Less experienced buyers sometimes reject production batches that fall within normal natural variation, creating disputes that could have been avoided with clearer sample approval documentation.

The practical consequence of underestimating sample approval time is that production slots get pushed back. Factories operate on scheduled capacity—they allocate machine time and labour weeks in advance. When a buyer's sample approval takes three weeks longer than planned, their reserved production slot may no longer be available. The factory then needs to reschedule, potentially pushing the order into a busier period or after a holiday closure. What started as a sample delay cascades into a production delay, and the total lead time extends far beyond what the original timeline projected.

Understanding the full scope of production timelines for sustainable cutlery requires acknowledging that sample approval isn't a fixed duration—it's a variable process influenced by specification clarity, communication efficiency, geographic distance, and internal decision-making speed. Buyers who budget two weeks for sample approval and actually experience six weeks aren't dealing with a slow factory; they're experiencing the normal reality of custom product development for natural materials.

The most effective approach involves building sample approval as a range rather than a fixed date, communicating specifications with visual references rather than text descriptions alone, establishing internal approval workflows before the sample arrives, and accepting that natural material products require more iteration than standardised synthetic alternatives. When these factors are accounted for upfront, the sample phase becomes a manageable part of the timeline rather than the point where schedules begin to slip.

Procurement teams that consistently meet their delivery targets tend to share one characteristic: they treat sample approval as a project phase with its own timeline buffer, not as a brief administrative step before "real" production begins. This shift in perspective—from viewing samples as a formality to understanding them as an iterative development process—is often the difference between orders that arrive on schedule and orders that generate last-minute scrambling.