Expert Quick Answer

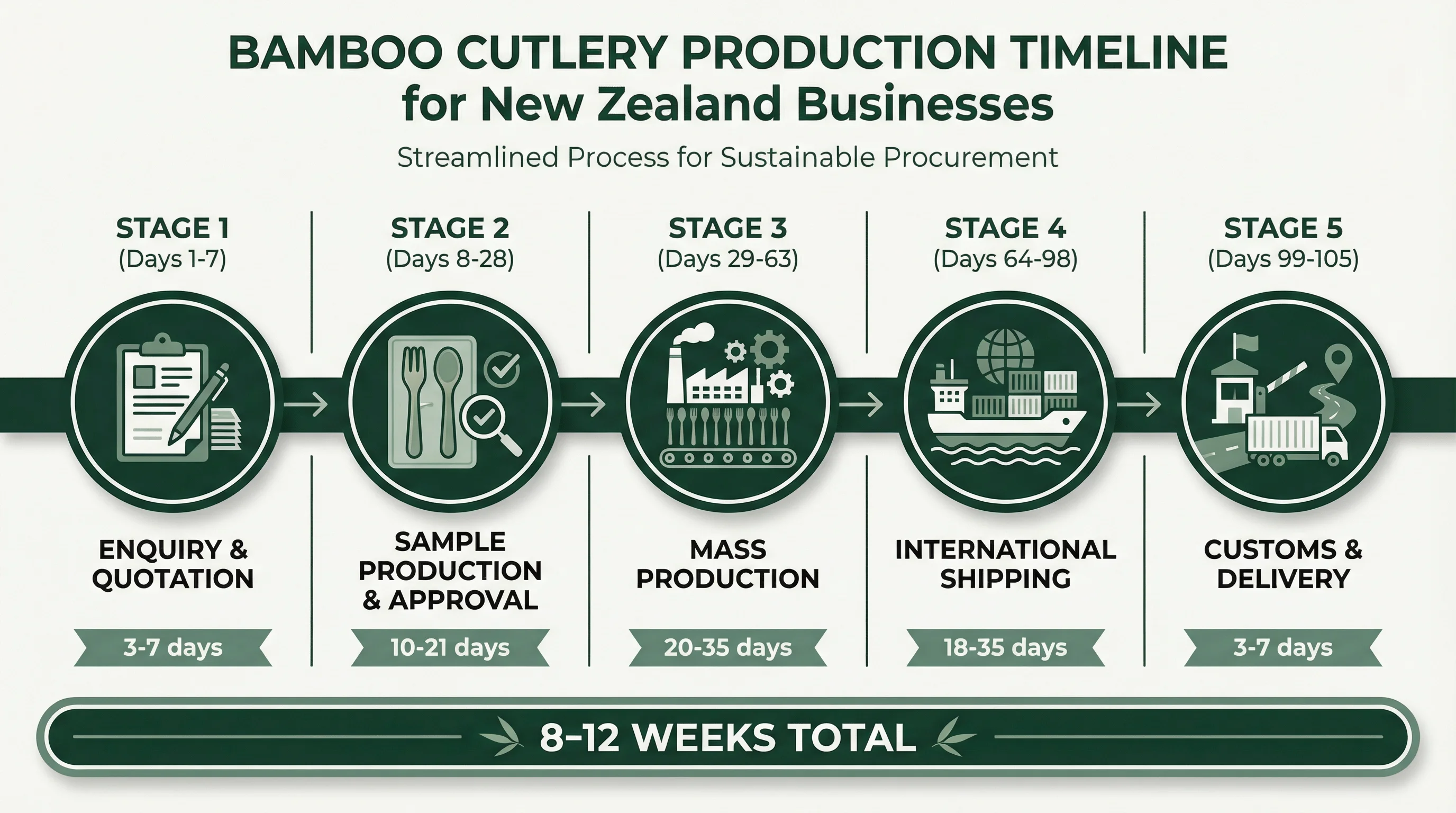

For New Zealand businesses ordering custom bamboo or sustainable cutlery, expect 8-12 weeks from initial enquiry to delivery. This timeline breaks down into five stages: sample production and approval (2-3 weeks), mass production (3-5 weeks), international shipping (3-4 weeks), and customs clearance plus local delivery (1-2 weeks). The variables that most significantly affect your timeline are customisation complexity, order volume, and seasonal factory calendars—particularly Chinese New Year, which can add 3-4 weeks to any order crossing that period.

Why Production Lead Time Is a Critical Decision Variable for NZ Businesses

In our experience working with New Zealand corporate buyers, the single most common source of procurement stress isn't price negotiation or quality concerns—it's timeline miscalculation. When a facilities manager discovers their sustainable cutlery order won't arrive before the company's annual conference, the consequences ripple through budgets, relationships, and brand commitments.

Understanding lead time isn't simply about knowing how many days production takes. It requires grasping the entire supply chain from bamboo forest to Auckland warehouse, recognising where delays commonly occur, and building realistic buffers into your procurement calendar. This knowledge transforms lead time from an anxiety-inducing unknown into a manageable planning variable.

Event Planning

Corporate events, conferences, and product launches have fixed dates. Late delivery means missed opportunities and emergency alternatives at premium prices.

Budget Accuracy

Rush fees, air freight premiums, and last-minute alternatives can inflate costs by 30-50%. Accurate timeline planning protects your procurement budget.

Quality Assurance

Rushed production increases defect rates. Adequate lead time allows for proper quality control, sample approval, and issue resolution before mass production.

The Complete Production Timeline: From Enquiry to Delivery

Every sustainable cutlery order follows a predictable sequence of stages. Understanding each phase—and where flexibility exists—allows you to make informed decisions about timing, cost, and risk tolerance.

Complete production timeline for sustainable cutlery orders to New Zealand

Stage 1: Initial Enquiry and Quotation (3-7 Days)

The procurement process begins with specification development and supplier communication. During this phase, you'll define product requirements, request quotations, and evaluate options. For straightforward orders using standard products, this stage can complete within 3-4 business days. Custom specifications requiring factory consultation may extend to 7 days or longer.

Practical tip: Prepare detailed specifications before contacting suppliers. Include material preferences, dimensions, logo artwork (in vector format), quantity requirements, and target delivery date. Complete information accelerates quotation turnaround significantly.

Stage 2: Sample Production and Approval (10-21 Days)

Before committing to mass production, most buyers request samples—and this is strongly recommended for any custom-branded order. Sample production typically requires 5-7 working days at the factory. Shipping samples to New Zealand via air express adds another 5-10 days depending on courier service and customs processing.

Once samples arrive, allow time for internal review and approval. If modifications are needed, the cycle repeats. In our experience, first-time orders average 1.5 sample rounds—the initial sample plus one revision. Budget your timeline accordingly.

Stage 3: Mass Production (20-35 Working Days)

Production time varies significantly based on order volume, customisation complexity, and factory capacity. Standard orders of 5,000-10,000 units typically complete within 20-25 working days. Larger orders exceeding 50,000 units may require 35-45 working days. Custom features such as multi-colour printing, special packaging, or unusual dimensions add processing time.

Production Time by Order Size

| Order Volume | Standard Products | Custom Branded |

|---|---|---|

| 1,000-5,000 units | 15-20 days | 18-25 days |

| 5,000-20,000 units | 20-25 days | 25-30 days |

| 20,000-50,000 units | 25-30 days | 30-35 days |

| 50,000+ units | 30-40 days | 35-45 days |

Stage 4: International Shipping (18-35 Days)

New Zealand's geographic position creates shipping realities that mainland buyers don't face. Sea freight from major Chinese ports (Ningbo, Shanghai, Shenzhen) to Auckland or Tauranga typically requires 18-25 days transit time. Add 3-5 days for port handling at both ends, and 2-5 days for customs clearance and biosecurity inspection.

Air freight offers a faster alternative at significantly higher cost. Transit time reduces to 3-5 days, but freight charges increase from approximately $0.50-1.50 per kg (sea) to $4-8 per kg (air). For urgent orders or high-value items, air freight may be justified. For standard bulk orders, sea freight remains the economical choice.

Stage 5: Customs and Local Delivery (3-7 Days)

Upon arrival in New Zealand, goods must clear customs and biosecurity inspection. Natural materials like bamboo and wood require MPI (Ministry for Primary Industries) clearance, which typically adds 1-2 days compared to synthetic products. Proper documentation—including phytosanitary certificates and treatment declarations—is essential to avoid delays.

Final delivery from port to your premises depends on location and logistics arrangements. Auckland-based businesses may receive goods within 1-2 days of customs clearance. South Island or regional deliveries may require 3-5 additional days.

Critical Factors That Can Extend Your Timeline

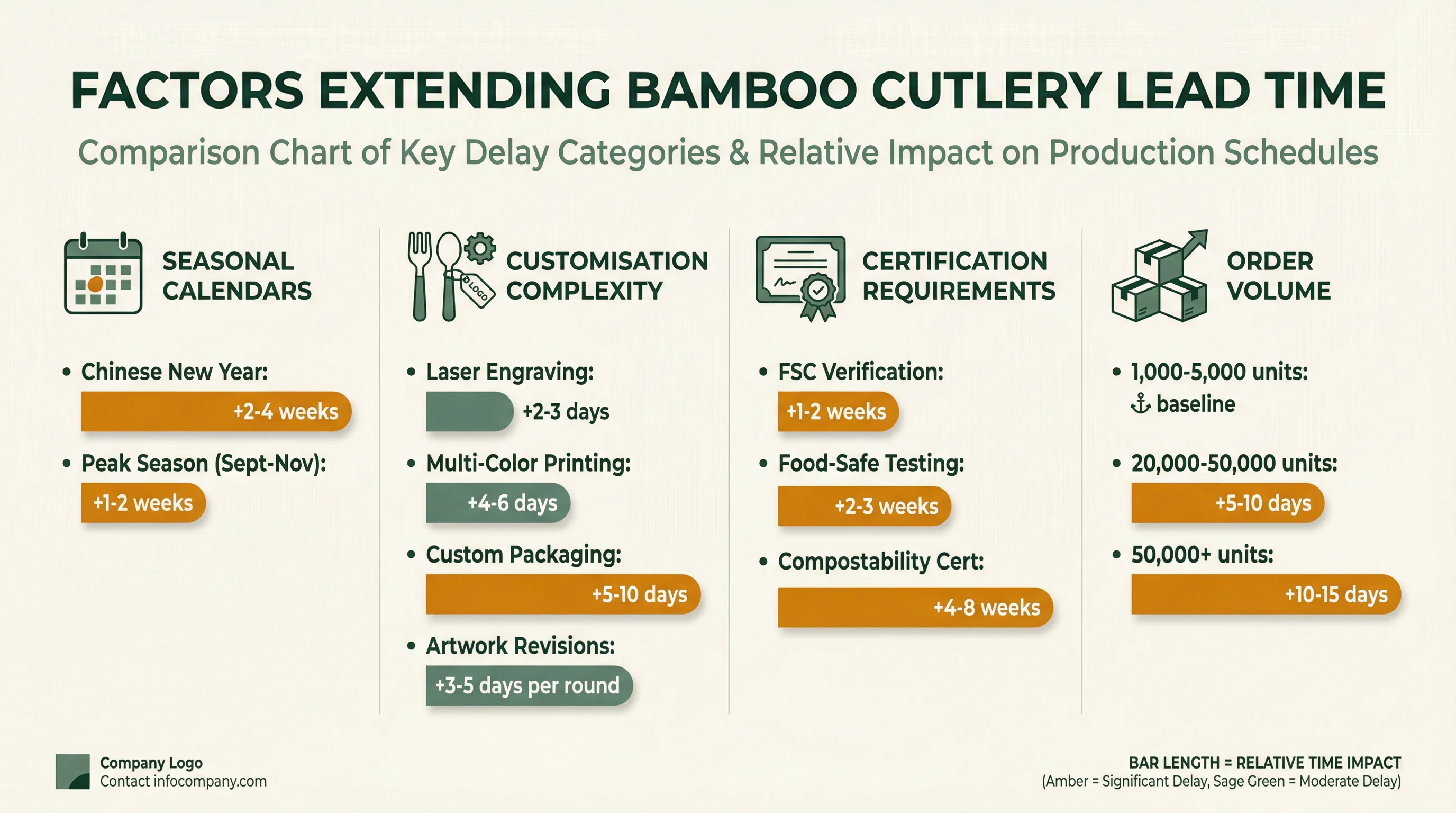

While the stages above represent typical timelines, several factors can significantly extend your lead time. Recognising these variables allows you to plan appropriate buffers and make informed trade-off decisions.

Key factors that can extend sustainable cutlery lead times

Seasonal Factory Calendars

Chinese New Year represents the most significant calendar disruption for bamboo cutlery procurement. Factories typically close for 2-4 weeks (late January to mid-February), with production queues building before and after the holiday. Orders placed in December may not enter production until late February. For events in Q1, place orders by early November.

Peak season (September through November) brings extended lead times as global buyers prepare for year-end events and holiday gifting. Factory capacity fills quickly, and production slots may require booking 2-3 weeks earlier than off-peak periods.

Customisation Complexity

Not all customisation adds equal time. Laser engraving on bamboo is relatively quick (adds 2-3 days for setup and processing). Multi-colour pad printing requires separate passes and drying time (adds 4-6 days). Custom packaging with printed boxes or sleeves may require parallel production and coordination (adds 5-10 days).

The most significant customisation delay often comes from artwork revisions. Each round of logo adjustments can add 3-5 days. Providing production-ready artwork (vector format, correct dimensions, approved colours) eliminates this common bottleneck.

Certification Requirements

If your organisation requires specific certifications, factor these into your timeline. FSC certification verification typically adds 1-2 weeks if the supplier needs to source certified materials specifically for your order. Food-safe testing for new product configurations requires 2-3 weeks. Compostability certification (BPI, OK Compost) for products not already certified can take 4-8 weeks.

Working with suppliers who maintain current certifications on standard products eliminates most certification delays. Verify certification status during the quotation phase rather than discovering gaps after order placement.

Common Timeline Mistakes

The most frequent planning error we observe is counting calendar days rather than working days. A "30-day production time" means 30 working days—approximately 6 weeks on the calendar. Add weekends, public holidays, and potential factory closures, and actual elapsed time often exceeds expectations by 40-50%.

Timeline Strategies for Different Organisation Types

The optimal approach to lead time management varies based on your organisation's size, order frequency, and risk tolerance. Here's how different buyer profiles typically navigate timeline challenges.

SMEs and First-Time Buyers

For organisations placing their first sustainable cutlery order or ordering infrequently, timeline risk is highest. Without established supplier relationships or experience navigating the process, unexpected delays are common.

- Add 3-4 weeks buffer beyond calculated timeline

- Consider NZ-based distributors with local stock for urgent needs

- Request detailed timeline breakdown in writing before ordering

- Start with standard products before attempting complex customisation

Large Enterprises and Regular Buyers

Organisations with ongoing sustainable cutlery requirements can leverage volume and relationship to optimise timelines. Established supplier partnerships often include priority production slots and more accurate forecasting.

- Negotiate blanket orders with scheduled releases

- Maintain safety stock in NZ for urgent requirements

- Book production slots 2-3 months ahead during peak seasons

- Establish backup supplier relationships for redundancy

New Zealand-Specific Timeline Considerations

New Zealand's geographic isolation and biosecurity requirements create unique timeline factors that mainland buyers don't encounter. Understanding these NZ-specific elements is essential for accurate planning.

Biosecurity and MPI Requirements

Natural materials entering New Zealand must satisfy Ministry for Primary Industries (MPI) biosecurity requirements. Bamboo and wood products require documentation confirming appropriate treatment (typically heat treatment or fumigation) to prevent pest introduction. Properly documented shipments clear biosecurity within 1-2 days. Missing or incomplete documentation can result in holds lasting 1-2 weeks while issues are resolved.

Practical guidance: Confirm your supplier provides phytosanitary certificates and treatment declarations as standard practice. Request copies of these documents before shipment to verify completeness.

Shipping Route Realities

New Zealand sits at the end of most shipping routes, which affects both transit time and schedule reliability. Vessels serving NZ ports often make multiple stops (Australia, Pacific Islands) before arrival, and schedule disruptions upstream cascade to NZ deliveries. During peak shipping seasons, vessel space to NZ can be constrained, potentially adding 1-2 weeks to booking times.

Holiday Calendar Differences

New Zealand's holiday calendar differs from both Asian manufacturing regions and Northern Hemisphere markets. The Christmas-New Year period (late December through early January) sees reduced logistics capacity domestically, while Asian factories operate normally. Conversely, Chinese New Year disrupts production while NZ operations continue. Plan orders to avoid having critical milestones fall during either region's holiday periods.

Typical shipping routes and transit times to New Zealand

Frequently Asked Questions

How long does it take to produce custom bamboo cutlery for New Zealand delivery?

For custom bamboo cutlery orders to New Zealand, expect 8-12 weeks total lead time. This includes sample production (5-7 days), sample shipping (5-10 days), mass production (20-35 days), sea freight (18-25 days), and customs clearance (2-5 days). Rush orders via air freight can reduce this to 5-6 weeks at higher cost.

What factors most significantly affect bamboo cutlery production time?

The three biggest factors are: customisation complexity (logo engraving adds 3-5 days vs plain products), order quantity (orders over 50,000 units may require 40+ production days), and seasonal timing (Chinese New Year causes 2-4 week factory closures, and September-November is peak season with extended lead times).

Can I get bamboo cutlery faster if I have an urgent deadline?

Yes, but with trade-offs. Rush production fees typically add 15-25% to costs. Air freight instead of sea freight adds $3-8 per kg but saves 2-3 weeks. Some suppliers maintain NZ warehouse stock for immediate dispatch of standard items. Always discuss urgent timelines before placing orders.

How does Chinese New Year affect bamboo cutlery lead times?

Chinese New Year (late January to mid-February) causes 2-4 week factory closures across Asia. Production queues build up before and after the holiday. For events in February-April, place orders by early December. Many experienced buyers add 3-4 weeks buffer to any timeline that crosses this period.

What certifications add time to bamboo cutlery production?

FSC certification verification adds 1-2 weeks if documentation isn't pre-arranged. Food-safe testing for new products requires 2-3 weeks. Custom compostability certification (BPI, OK Compost) can take 4-8 weeks. Working with suppliers who maintain current certifications eliminates most of these delays.

How should I plan backwards from my event date?

Start with your event date and work backwards: subtract 1 week for internal distribution, 3-4 weeks for shipping and customs, 4-5 weeks for production, 2-3 weeks for sample approval, and 1-2 weeks for initial enquiry and quoting. This gives you 11-15 weeks minimum. Add 2-3 weeks buffer for unexpected delays.

Planning Your Next Sustainable Cutlery Order

Production lead time for sustainable cutlery is predictable once you understand the variables involved. The 8-12 week standard timeline provides a reliable planning baseline, with adjustments for customisation complexity, seasonal factors, and your organisation's risk tolerance.

The most successful procurement outcomes we observe come from buyers who start early, communicate clearly with suppliers, and build appropriate buffers into their timelines. When timeline pressure does arise, having established supplier relationships and understanding the available trade-offs (rush fees, air freight, specification simplification) enables informed decisions rather than panic responses.

For organisations beginning their sustainable cutlery procurement journey, understanding lead time alongside minimum order requirements provides the foundation for effective planning. Both variables interact—larger orders that achieve better per-unit pricing also require longer production times—and balancing these factors against your specific requirements is where procurement expertise delivers value.