Why Your Confirmed Bamboo Cutlery Order Won't Start Production Tomorrow

The invisible scheduling system that determines when your order actually enters the production line.

When a procurement manager receives order confirmation from a bamboo cutlery supplier, there's often an assumption that production will begin within days—perhaps after materials are gathered and the production line is prepared. This assumption creates one of the most persistent gaps between expected and actual delivery timelines. The reality involves a scheduling system that most buyers never see: the production queue.

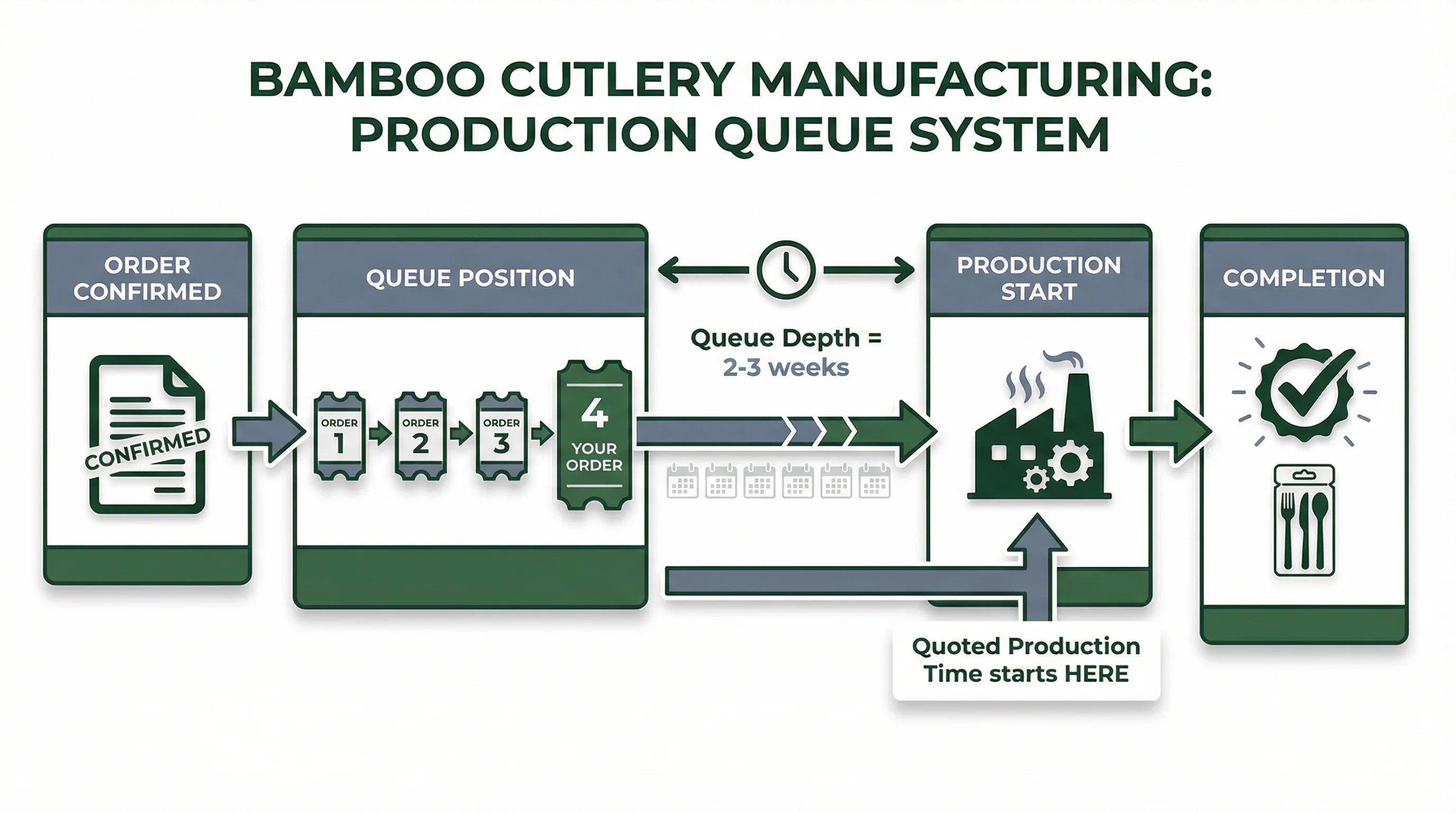

From a factory operations perspective, order confirmation and production start are separated by a variable that rarely appears in quotations or purchase agreements—queue position. Every manufacturing facility operates with finite capacity, and that capacity is allocated weeks or months in advance. When your order is confirmed, it enters a queue behind existing commitments. The time between confirmation and production start isn't idle waiting; it's your order moving through a scheduling system that prioritises based on confirmation date, production complexity, and sometimes relationship history with the buyer.

The queue system exists because bamboo cutlery production requires coordinated resources that can't be instantly redirected. A production line configured for laser-engraved forks needs specific tooling, trained operators, and prepared materials. Switching between product types involves setup time, quality calibration, and often material changeover. Factories batch similar orders together to maximise efficiency, which means your 5,000-unit order might wait until it can be grouped with other similar specifications—even if the line technically has capacity.

In practice, this is often where lead time calculations start to diverge from reality. A factory quoting "20-25 working days production time" is describing the duration once your order reaches the front of the queue—not the total time from order confirmation. If the current queue depth is two weeks, your actual production timeline is closer to 35-40 working days. This distinction rarely appears in initial quotations because queue depth fluctuates based on current order volume, and factories are understandably reluctant to quote variable wait times that might discourage buyers.

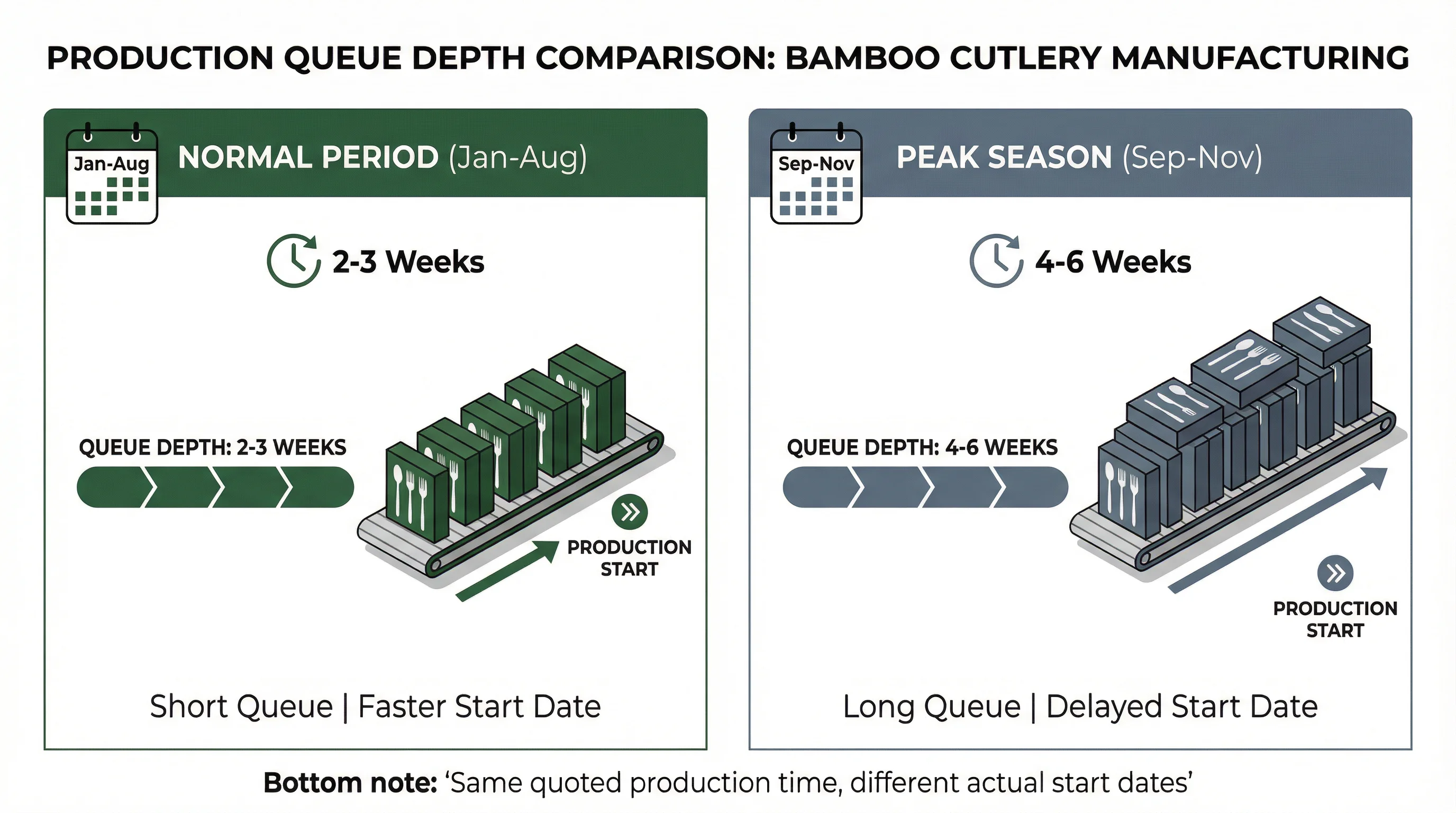

The queue position problem intensifies during peak seasons. Between September and November, when global buyers prepare for year-end events and holiday gifting, queue depths at established bamboo cutlery manufacturers can extend to four or six weeks. An order confirmed in early October might not enter production until late November, regardless of the quoted production duration. Buyers who plan backwards from their event date using only the stated production time find themselves facing impossible timelines when the queue reality becomes apparent.

Understanding production timelines for sustainable cutlery requires recognising that the factory's quoted lead time is one component of total delivery time—and often not the component that causes delays. The queue position determines when production actually begins, and this information is rarely volunteered unless specifically requested.

Several factors influence your position in the production queue beyond simple confirmation date. Order size matters—larger orders often receive priority because they represent more efficient use of production line setup time. Repeat customers with established relationships may receive preferential scheduling, particularly when capacity is constrained. Payment terms also play a role; orders with deposits already received typically advance faster than those awaiting payment processing.

The practical consequence of queue position blindness is that buyers consistently underestimate total lead time by two to four weeks. This gap compounds when combined with other timeline variables—sample approval delays, shipping transit, customs clearance. An order that should theoretically arrive in eight weeks actually takes twelve, and the queue position component is often the hidden contributor that nobody identified during planning.

Experienced procurement teams address this by asking a specific question during the quotation process: "What is your current production queue depth, and when would our order realistically enter production if confirmed this week?" This question forces transparency about scheduling reality rather than theoretical production duration. The answer provides the missing variable needed for accurate timeline planning—and occasionally reveals that a supplier with a longer quoted production time but shorter queue might actually deliver faster than a supplier advertising quick turnaround.

For New Zealand buyers specifically, the queue position variable adds particular risk because of the geographic distance. A two-week queue delay in China translates to a two-week delay in Auckland delivery—but the consequences of missing a deadline are harder to mitigate from 10,000 kilometres away. Rush shipping can compress transit time, but it cannot compress the queue. Once your order is waiting behind other commitments, the only options are patience or premium fees to jump the queue—and not all factories offer queue-jumping as an option.

The most effective approach to managing queue position involves timing your order confirmation strategically. Confirming orders during off-peak periods (typically January-February after Chinese New Year recovery, and June-August before peak season begins) often means shorter queues and faster production starts. Building relationships with suppliers who communicate queue status transparently allows for more accurate planning. And budgeting timeline with explicit queue buffer—adding two to three weeks beyond the quoted production time—provides realistic expectations rather than optimistic projections that consistently disappoint.