How Artwork Revisions Compound Your Bamboo Cutlery Lead Time

That "quick logo adjustment" just added two weeks to your timeline. Understanding why design changes create delays that multiply rather than add.

When procurement teams receive a production timeline for custom bamboo cutlery, the quoted lead time typically assumes artwork approval happens once. The reality is that most orders go through two to four revision cycles before final approval, and each cycle doesn't simply add a few days—it triggers a cascade of delays that compound in ways the original timeline never accounted for. This is where lead time estimates begin to diverge significantly from actual delivery dates.

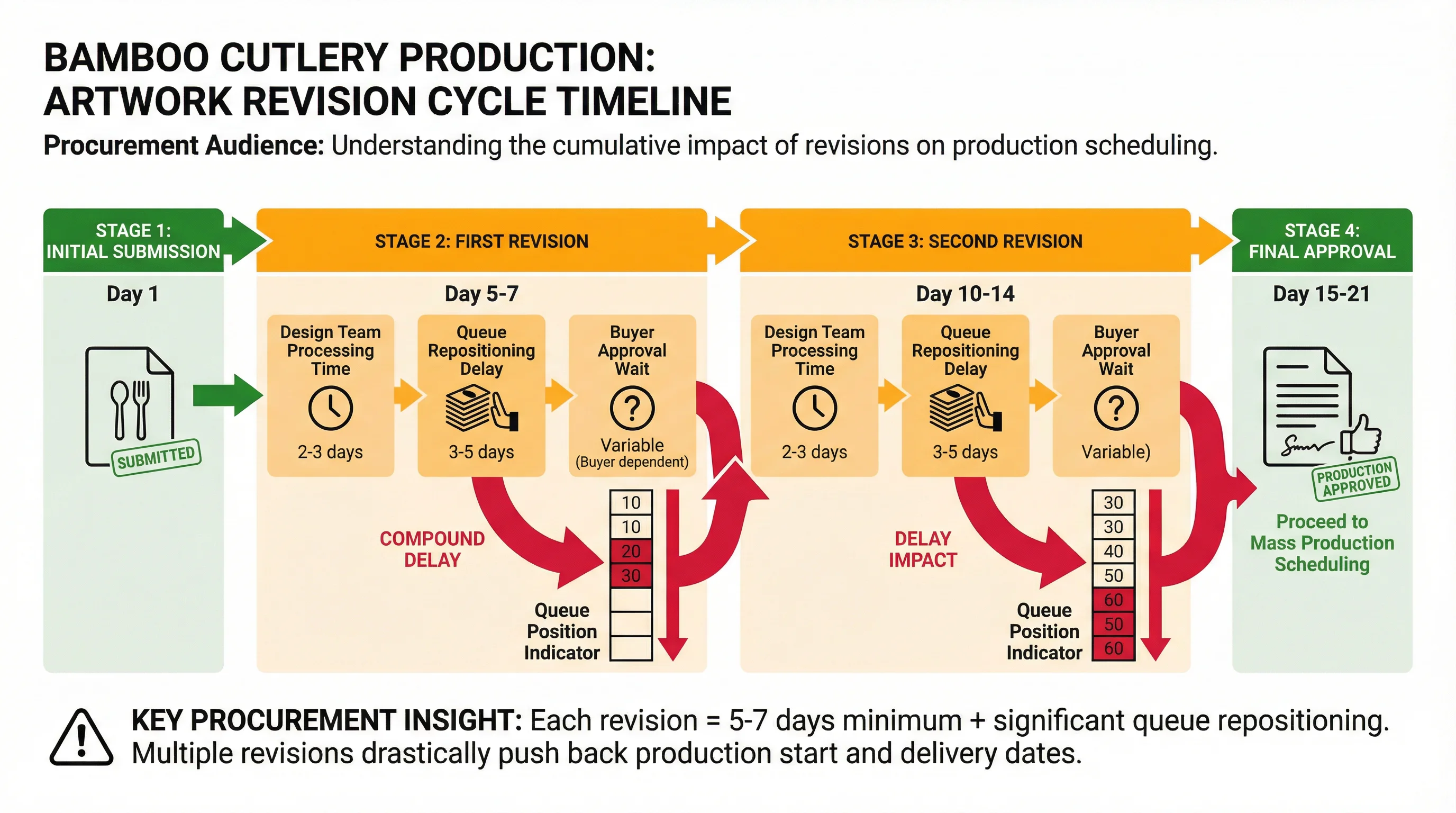

The misunderstanding starts with how buyers perceive artwork revisions. A request to adjust logo placement or modify a colour shade feels like a minor change—something that should take an hour or two to implement. From the factory floor perspective, however, each revision initiates a complete restart of the pre-production approval sequence. The revised artwork must be processed by the design team, converted to production-ready files, reviewed by quality control, and then re-submitted for buyer approval. This cycle takes three to five business days minimum, regardless of how small the change appears.

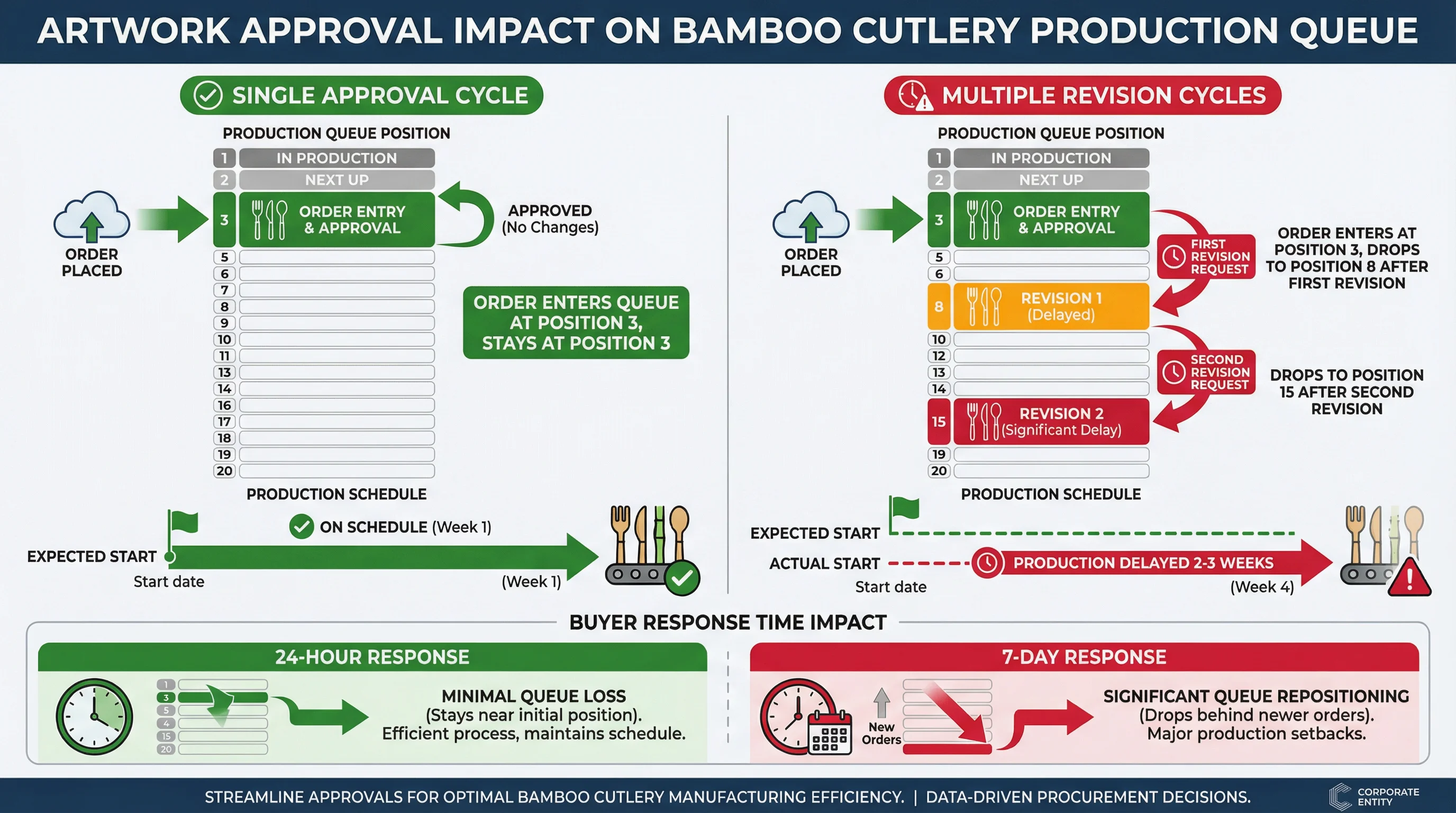

The compound effect becomes apparent when you trace what happens during those three to five days. The production slot that was tentatively reserved for your order doesn't remain empty while awaiting artwork approval. Factory scheduling operates on a continuous flow basis—when one order's artwork enters revision, the next order in queue moves forward. By the time your revised artwork receives approval, your original production slot has been filled by another order. You're now waiting for the next available slot, which might be five to seven days later depending on factory capacity.

For bamboo cutlery specifically, artwork complexity introduces additional variables that buyers often don't anticipate. Unlike printing on paper or plastic, applying branding to natural bamboo requires accounting for material variation. The grain pattern, colour tone, and surface texture differ between bamboo pieces, which affects how laser engraving or pad printing appears on the final product. A logo that looks perfect in a digital mockup may require adjustment when applied to actual bamboo samples—and this adjustment triggers another revision cycle.

Colour matching presents a particularly challenging aspect of bamboo cutlery branding. Buyers frequently specify Pantone colours for their corporate branding, expecting exact replication on the finished product. However, bamboo's natural colour—ranging from pale cream to golden yellow depending on the specific culm and processing method—interacts with applied colours in ways that differ from standard printing substrates. A corporate blue that appears vibrant on white paper may look muted or shifted when applied to bamboo. Achieving acceptable colour matching often requires two to three test runs, each adding to the pre-production timeline.

The technical file requirements for bamboo cutlery production create another layer of potential revision cycles. Laser engraving requires vector files with specific line weights and spacing to produce clean results on bamboo's fibrous surface. Pad printing requires separated colour layers with appropriate trapping to prevent registration issues. Many buyers submit artwork files that work perfectly for digital or paper applications but require conversion and adjustment for bamboo production. This technical preparation adds time before the first proof can even be produced.

Understanding how bamboo cutlery production timelines work requires recognising that the artwork approval phase sits at the beginning of the production sequence, meaning delays here push back everything that follows. Unlike delays that occur during manufacturing—which might be partially absorbed through overtime or parallel processing—pre-production delays have no recovery mechanism. Every day spent in revision cycles is a day added directly to the final delivery date.

The buyer-side approval process often contributes more delay than the factory-side revision work. A revised proof might be ready within 48 hours, but if it sits in someone's inbox for a week awaiting internal sign-off, that week becomes part of the production timeline. Factories track artwork approval cycles carefully, and experienced project managers know that buyer response time is frequently the longest segment of the pre-production phase. Orders where the buyer responds within 24 hours move through approval in one to two weeks; orders where each response takes five to seven days can spend six weeks or more in the artwork phase alone.

Multi-stakeholder approval processes amplify this effect. When artwork requires sign-off from marketing, legal, and procurement departments—each with their own review timelines and potential change requests—the revision cycles multiply. A marketing team might approve the visual design only for legal to request changes to disclaimer text, which then requires marketing re-approval of the modified layout. Each internal handoff adds days, and each change request initiates a new factory revision cycle.

The practical implications for timeline planning are significant. A quoted eight-week production lead time assumes artwork approval within the first week. If artwork approval takes four weeks due to revision cycles, the actual delivery timeline extends to eleven or twelve weeks—not because production took longer, but because the starting point shifted. Experienced buyers build artwork approval buffer into their planning, often adding two to three weeks to quoted timelines specifically to account for revision cycles.

Reducing artwork revision cycles requires preparation before the first submission. Providing production-ready files in the correct format, specifying acceptable colour variation ranges rather than demanding exact Pantone matches, and consolidating internal approvals before submitting artwork all help minimise revision rounds. Some buyers request a bamboo sample before finalising artwork, allowing them to see how their branding will appear on the actual material and adjust expectations accordingly. This upfront investment in preparation typically saves more time than it costs by reducing downstream revision cycles.

The most effective approach treats artwork approval as a project phase with its own timeline, rather than a preliminary step that happens before "real" production begins. Allocating two to three weeks specifically for artwork approval—and communicating this timeline to internal stakeholders—creates realistic expectations and reduces the pressure that leads to rushed approvals followed by change requests. When artwork approval is treated as part of the production timeline rather than something that should happen instantly, the compound delay effect becomes manageable rather than disruptive.